AR09058350 «Development and implementation of technology for the production of chromium antifriction cast iron for parts of mining equipment» s.w. Shcherbakova E.P.

Relevance

A number of parts for mining equipment are made from chromium cast iron. Despite the significant advantages of using these cast irons, they also have their disadvantages – relatively poor casting properties (low fluidity, high shrinkage), and cutting processing in the manufacture of parts from castings is difficult

Objective of the project

Development and implementation of technology for the production of mining equipment parts from chromium cast iron with an optimal set of properties depending on the operating conditions of the parts, which will ensure an increase in service life by 1,5-2 times.

Expected and achieved results

The main technological parameters for the manufacture of parts for slurry pumps and the composition of the wear-resistant alloy were determined. The composition of the wear-resistant alloy was determined. The properties of the developed alloy were studied in laboratory conditions.

It was found that microalloying with titanium up to 0.2% leads to a significant refinement of the graphite phase and a slight increase in its quantity, which helps to increase the slip coefficient. Experimental studies have confirmed the beneficial effect of microalloying with titanium on the performance properties of anti-friction gray cast iron AChS-2. The introduction of titanium into the composition of Slav AChS-2 in an amount of 0.2% leads to grinding of the graphite phase, which has a beneficial effect on the slip coefficient and hardness of the alloy.

The properties of the developed alloy were studied in laboratory conditions. Alloy microstructures and data on the mechanical properties of parts were obtained.

The information analysis carried out suggested that microalloying with certain elements will make it possible to refine the graphite phase and make it more uniform in size. For this purpose, the following experiment was carried out. An experimental alloy was smelted in laboratory conditions; in comparison with the composition of classic AChS-2 cast iron, the titanium content in the experimental alloy was increased to 0.2%, i.e. almost 2 times. The required titanium content was ensured by the introduction of FeT70 ferrotitanium.

The presence of titanium should contribute to the grinding of graphite and, thus, indirectly affect the mechanical properties of cast iron, in particular the slip coefficient.

The alloy was smelted in a UIP-25 induction furnace, and casting was carried out into a sand-clay mold. The casting conditions did not change during the experiment. After complete cooling, samples were prepared to study the microstructure and mechanical properties. Sections were prepared on a Strue metallographic complex; Thixomet Pro software was used for metallographic analysis; hardness was determined on a Wilson hardness tester. The slip coefficient was determined using a COF-P01(M) device with the following characteristics: dry friction (without lubrication), inclination angle – 150; angular velocity – 100/s. The base alloy AChS-2 was used as a comparison sample.

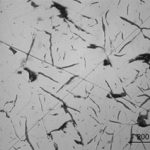

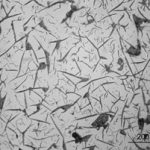

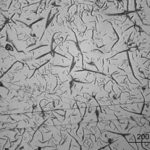

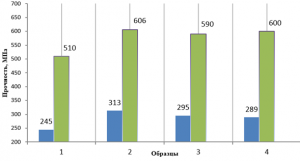

The results of microstructure studies showed that the average length of graphite inclusions in the experimental alloy was 27 μm. Compared to the base alloy AChS-2, the length of graphite inclusions decreased by 4 times. At the same time, the area occupied by graphite increased slightly, by about 10%, which indicates an increase in the amount of free graphite phase. The sliding coefficient in the experimental alloy increased by 35%, which indicates its higher antifriction properties, while the hardness of the experimental sample increased slightly, by about 12%.

Figure 1. Microstructures of the studied samples (a-e)

Research group

- Elena Petrovna Shcherbakova – scientific supervisor, PhD, e.d. Associate professor of the department of Science and Technology

ORCID 0000-0001-6678-6673

Researcher ID N-5639-2017

Scopus Author ID 55543103900

- Dostayeva Ardak Mukhamediyevna – responsible executive, PhD, e.d. Associate professor of NMD

ORCID 0000-0002-1982-2368

Researcher ID AAB-9478-2020

Scopus Author ID 57160297400

- Issagulova Diana Aristotleyevna – scientific consultant, PhD, associate professor of the department of NMD

Scopus Author ID 55778253200

- Adamova Gulden Khassenovna – doctoral student gr. METD-21 department of NMD

- Kovaleva Tatyana Viktorovna – doctoral student gr. METD-19 department of NMD

Scopus Author ID 57211297553

- Aubakirov Dastan Rakhmetollaevich – doctoral student gr. METD-19 department of NMD

ORCID0000-0003-4193-5956

Researcher ID X-1767-2019

Scopus Author ID 57194209750

- Alina Arailym Altynbekovna – doctoral student gr. METD-20 department of NMD

ORCID 0000-0003-3577-4914

Scopus Author ID 57218196165

List of publications

- Shcherbakova E.P., Kwon S.S., Kovalev P.V., Dostayeva A.M., Aubakirov D.R. The influence of alloying on the parameters of graphite inclusions and some properties of gray cast iron // Proceedings of the University, Karaganda: Publishing House of KarTU. – 2022, № 3, pp. 68-72

- Kwon S.S., Shcherbakova E.P. Study of the properties of ASF-2 alloyed with titanium // Proceedings of the International scientific and practical conference «Integration of science, education and production – the Basis for the Implementation of the Nation’s Plan» (Saginov Reading №14) June 16-17, 2022, pp. 209-210.

- Y.P. Chsherbakova, S.S. Kvon, AM Dostayeva, DR Aubakirov Studying the grafite phase in antifriction AChS – 2 cast iron // Metalurgy, Croatia: Croatian Metallurgical Society. – 2022. – №1 (61). – P. 200-202 (IF Scopus 0.388, Scopus percentile – 37th).

Information for potential users

The results obtained can be implemented in other foundry technologies, used in the development of new alloys, and in the development of new pouring and melting modes. The theoretical and practical results obtained will be used in industry, in engineering calculations and for educational purposes.

AP09058352 «Development and implementation of a new heat-resistant alloy and technology for producing parts for metallurgical production based on it» s.w. Arinova S.K.

Relevance

The relevance of this topic is due to the need to search for new compositions of heat-resistant steels that are optimal in terms of price/quality. In other words, it is necessary to increase the heat resistance of existing and currently used heat-resistant steels with a minimal increase in their cost. The problem is aggravated by the fact that in the Republic of Kazakhstan the production of heat-resistant steels is practically not established. Consequently, the developed alloy should not have a too complex composition, so that the technology for its production and castings from it can be adapted and implemented at existing enterprises of the Republic of Kazakhstan, taking into account the level of development of fixed assets.

Objective of the project

Creation of new improved heat-resistant alloys, as well as technologies for the production of parts based on them, taking into account existing fixed assets in the territory of the Republic of Kazakhstan (Karaganda region).

Expected and achieved results

A new material composition has been proposed for the manufacture of a model for casting using the LGM method, consisting of a mixture of foundry and construction polystyrenes such as A-105, PSM-115, PSE-4 in a ratio of 3:1 with a fraction of no more than 0.7 mm.

A technology has been developed for the production of castings from a heat-resistant alloy, including smelting in chipboard; ultrasonic treatment of the melt at a processing frequency of 80 – 90 kHz and amplitude – 110 – 120 µm; obtaining castings using the LGM method; heat treatment, consisting of hardening at a temperature of 1150 – 1200 0C, oil and subsequent tempering at 500 – 520 0С, air. A process flow chart has been developed and approved.

Research group

- Arinova Saniya Kaskatayevna – scientific supervisor, PhD, teacher of the Department of Scientific and Technical Technologies

Scopus Author ID 57192206332

- Aubakirov Dastan Rakhmetollaevich – responsible executor, senior lecturer of the NTM department

ORCID0000-0003-4193-5956

Researcher IDX-1767-2019

Scopus ID 57194209750

3.Sultangaziyev Ruslan Bauyrzhanovich- PhD, e.d. Associate professor of the department of Science and Technology

ORCID0000-0002-3928-486X

Scopus Author ID57160291200

4.Issagulova Diana Aristotleevna – PhD, Associate professor of the department of Science and Technology

Scopus Author ID 55778253200

- Kovaleva Tatyana Viktorovna – teacher of the Department of Scientific and Technical Technologies

Scopus Author ID 57211297553

- Alina Arailym Altynbekovna – doctoral student gr. MetD-20 of the Department of NMD ORCID 0000-0003-3577-4914

Scopus Author ID 57218196165

7.Sultanbek Togzhan Zhurtshybaidyzy– doctoral student gr. MetD-21 department of NMD

List of publications

- Arinova S.K., Aubakirov D.R., Issagulova D.A. Development of a heat-resistant alloy and technology for producing parts for metallurgical production based on it // Monograph. Kazakhstan. Ed. IP KarTU, 2022. 77 p. ISBN 978-601-355-150-0.

- S.K. Аrinova, Sv.S Kvon, DR Aubakirov, T.V. Kovaleva, DA Issagulova Investigation of heat-resistant properties and microstructure of experimental steel based on the Cr-Ni-Ti-Nb system obtained under industrial conditions // Metalurgy, Croatia: Croatian Metallurgical Society. – 2023. – No. 3-4 (62). – P. 471 – 473, (IF Scopus 0.388, Scopus percentile – 35th)

- Arinova S.K., Dostayeva A.M., Issagulova D.A. Development of a new heat-resistant alloy and technology for producing parts based on it // Monograph. Germany: Ed. LAP LAMBERT, 2023. ISBN 978-620-5-52567-8.

- Arinova S.K., Kwon S.S., Kulikov V.Y., Issagulova D.A., Aubakirov D.R., Alina A.A. The influence of the model material and paint composition during wood casting on the quality of the casting // Foundry Production, Moscow: Publishing House «Liteinoe Proizvodstvo». – 2023. – No. 5. – P. 32-34.

- Kvon SS, Arinova SK, Aubakirov DR, Kovaleva TV Influence of Niobium on Heat-Resistant Properties of Steel Cr18Ni10Ti // Metallurgist, Vol. 66(11-12), 2023, pp. 1552–1556. (IF Scopus percentile – 46th).

Information for potential users

The obtained scientific results can be applied in the development of new industries and areas of metallurgical and foundry production.